A concrete block is a building block made of cement and aggregate. Concrete blocks are used in construction, for example as a formwork for reinforced concrete or as the structural element in post-and-beam structures.

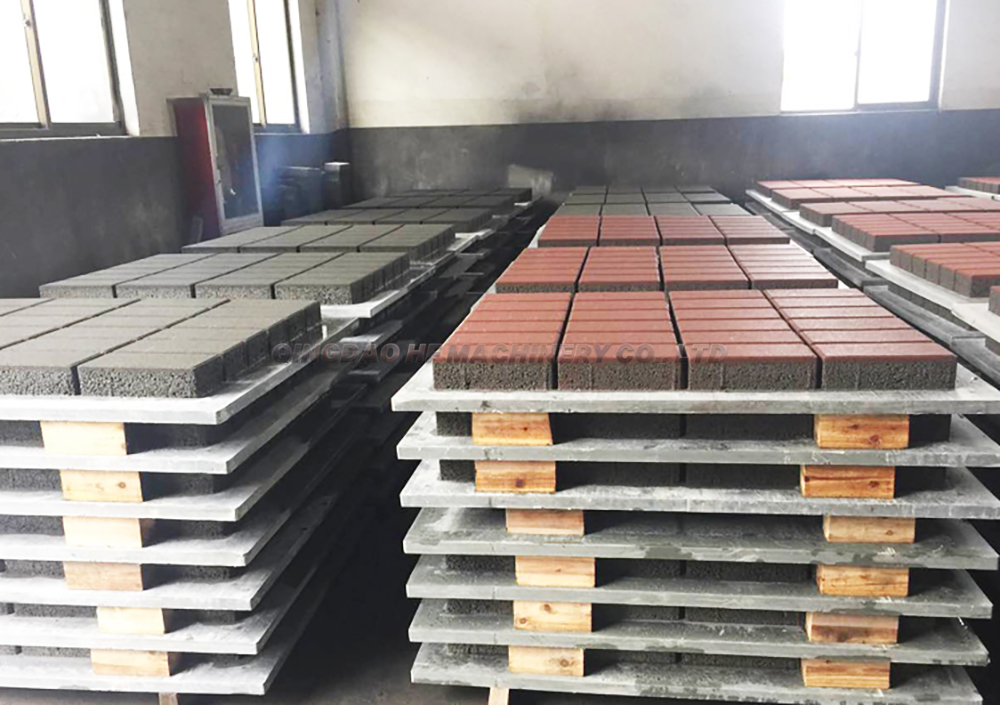

Concrete brick curing process:

After the concrete blocks are transported to the maintenance site for stacking, wait for the strength of the concrete blocks to increase.

Usually, watering is not required on the first day, because the cement of the concrete blocks is easily washed away.

If it is maintained in the open field, it is best to cover it with straw curtains or plastic.

The membrane remains moist.

After 6-8 hours or the next day, when the strength of the concrete blocks is sufficient, the blocks slabs are separated and the blocks are stacked,

and watering and maintenance can be started.

There is no time limit in the open field, mainly to keep the bricks moist,

usually 2-3 times, for at least 7-10 days, the curing strength of concrete blocks can reach about 70%.

The state stipulates that curing is required for 28 days, but usually it will be sold in 7-10 days.

So you need to keep the blocks moist all the time.

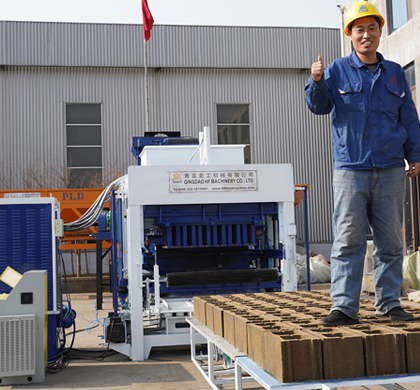

Block machines play a crucial role in modern construction, facilitating the production of various types of blocks used in buildings, roads, and infrastructure projects. To ensure optimal efficiency and longevity of these machines, it's essential to unders

There are several types of block machines used in various industries for producing different types of blocks, such as concrete blocks, cement blocks, and interlocking blocks. Some common types include:

The first step in maximizing the potential of a brick making machine is to select the right machine for the job. Consider factors such as the size of the bricks you need to produce, the production capacity required, and the specific features and capabilit

Whether for inquiries for inspections and

maintenance, for individual plant optimizations or

extensions, or spare and wear parts.

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.